How used bulk containers improve storage efficiency across industries

Wiki Article

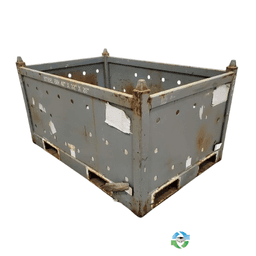

The Ultimate Overview to Picking the Right Mass Containers for Your Company Needs

Selecting the ideal bulk containers is vital for any organization that relies upon efficient logistics. Different kinds of containers exist, each created for particular materials and applications. Elements such as dimension, material compatibility, and regulative criteria play a substantial function in this decision-making process. Recognizing these aspects can bring about boosted functional performance. Many organizations neglect essential elements that can boost their overall effectiveness and sustainability. What are these considerations?Recognizing Different Sorts Of Bulk Containers

Mass containers serve as important tools for businesses seeking reliable storage and transportation solutions. These containers are available in numerous types, each designed to meet certain functional requirements. One usual type is the intermediate mass container (IBC), which is ideal for granulated and liquid products, using a balance of ability and ability to move. Another popular option is the mass bag, or FIBC, suitable for completely dry, flowable items. These versatile containers are light-weight and can be quickly carried and kept. For much heavier products, inflexible mass containers are usually employed, giving resilience and security for safe handling. In addition, there are specific containers tailored for harmful materials, making certain compliance with safety and security regulations. Comprehending the distinctive features of these bulk container kinds allows businesses to make informed choices that enhance logistics and decrease expenses. By choosing the ideal container, companies can boost their functional performance and enhance their supply chain procedures.Secret Material Considerations for Bulk Containers

When picking mass containers, it is necessary to consider the products utilized in their building and construction. Variables such as toughness, toughness, and chemical compatibility play an essential duty in ensuring the containers meet details functional demands. Furthermore, weight and transportability worries can impact both performance and transportation logistics.Material Toughness and Strength

Durability and stamina are essential aspects in choosing products for mass containers, as they straight influence the container's ability to endure various environmental problems and dealing with procedures. Materials such as high-density polyethylene (HDPE), polypropylene, and stainless steel are commonly preferred for their durable buildings, supplying resistance to temperature, effect, and abrasion fluctuations. The choice of product likewise influences the general life expectancy of the container; more powerful products typically result in much less constant replacements, leading to set you back savings over time. Additionally, the weight of the product can impact shipping costs and convenience of handling. Businesses must consider their particular operational atmospheres and the capacity for wear and tear to guarantee peak longevity and stamina in their mass container choice.Chemical Compatibility Aspects

Recognizing chemical compatibility is important for choosing mass containers, as the products utilized need to withstand the certain materials they will certainly hold. Numerous aspects influence compatibility, including the chemical nature of the components, temperature level, and period of storage. As an example, harsh chemicals might need containers made from stainless-steel or specialized plastics that stand up to degradation. In addition, reactive substances can create heat or gases, requiring aired vent or pressure-rated containers. The option of container material, whether polyethylene, polycarbonate, or steel, ought to align with the chemical buildings of the kept substances to stop violations or leaks. Eventually, a complete analysis of these compatibility variables guarantees secure handling and storage, protecting both employees and the atmosphere while preserving item honesty.Weight and Mobility Concerns

Choosing mass containers entails not only evaluating chemical compatibility yet also considering weight and mobility. Companies need to assess the simplicity of handling and transport to optimize effectiveness. Lightweight products like high-density polyethylene (HDPE) or light weight aluminum can facilitate simpler movement and reduce delivery costs. On the other hand, larger containers may supply boosted durability however can hinder flexibility, particularly in settings calling for frequent relocation. Furthermore, the layout of the container need to allow for hassle-free lifting and piling, making certain ergonomic safety and security for workers. Business should additionally consider the framework offered for transport; as an example, containers suitable with forklifts or pallet jacks can enhance operations. Eventually, the appropriate equilibrium in between weight and mobility straight affects functional performance and cost performance.Sizing Your Bulk Containers for Ideal Performance

When sizing bulk containers, companies have to thoroughly analyze the measurements required to suit their specific products. Additionally, weight capability is a critical variable that affects performance and safety and security during transport and storage. Reliable sizing not just makes the most of room but also enhances operational workflows.Identifying Container Dimensions

Picking the appropriate measurements for mass containers is crucial for maximizing efficiency in storage space and transport. Services must analyze their details demands, taking into consideration factors such as offered space, the nature of the goods being saved, and the methods of transport utilized. Exact measurements assure that containers fit ideally in storehouses and automobiles, reducing thrown away area and decreasing dealing with time. Requirement dimensions can offer benefit, but custom-made measurements may be essential for unique requirements or to fit specific items. Additionally, it is essential to examine piling capabilities and access, as these aspects affect total operational efficiency. Eventually, the appropriate dimensions result in boosted organization and structured logistics, profiting the total productivity of the company.Weight Ability Considerations

Comprehending weight capacity is crucial for companies intending to maximize their bulk container efficiency. The weight ability of a container straight affects storage space abilities, transportation logistics, and overall operational expenses. Picking containers with the suitable weight limits guarantees that organizations can securely save and carry their items without running the risk of damages or compliance concerns. Straining containers can result in structural failings, while underutilizing ability lead to lost sources. It is very important for organizations to analyze their item weights and consider any type of governing demands when picking containers. Furthermore, variables such as the kind of material, planned usage, and environmental conditions must likewise affect weight capability choices. By examining these aspects, businesses can boost performance and guarantee a streamlined supply chain.Governing Conformity and Security Standards

Governing compliance and safety and security standards play an important duty in the selection of mass containers for companies. Organizations has to ensure that their containers fulfill various guidelines set by neighborhood, nationwide, and international authorities. These requirements typically concern product safety, architectural stability, and correct labeling, which help avoid mishaps and ensure the secure transport of items.

Furthermore, adherence to industry-specific standards, such as those from the Fda (FDA) or the Occupational Safety and Wellness Management (OSHA), is essential for firms dealing with harmful materials or food. Non-compliance can cause penalties, lawful issues, or damage to a service's track record.

Businesses ought to likewise take into consideration the container's compatibility with the materials being saved or delivered to stay clear of contamination or chain reaction (used plastic containers). To summarize, understanding and executing regulatory conformity and security standards is crucial for the effective and responsible usage of bulk containers

Sustainability Options for Eco-Friendly Mass Containers

Business are additionally checking out alternatives made from recycled products, which not only save resources yet additionally support the recycling sector. Moreover, advancements in design permit for lighter containers that call for less power to transport, even more boosting sustainability. By integrating these environmentally friendly bulk container alternatives, organizations can demonstrate their dedication to ecological stewardship while fulfilling customer need for sustainable practices. This shift not just helps the planet however can also boost brand reputation and consumer loyalty.

Cost-Effectiveness and Budgeting for Bulk Containers

While lots of services focus on sustainability, cost-effectiveness continues to be a vital aspect when picking mass containers. Organizations must analyze the first acquisition price, in addition to long-lasting functional costs, to guarantee financial feasibility. Elements such as reusability, upkeep, and durability play a substantial duty in establishing total costs.Spending in high-grade containers might yield greater in advance expenses yet can result in cost savings with reduced replacement rates and lowered waste. Additionally, companies need to take into consideration transportation prices and storage effectiveness, as these can affect the general budget plan.

Frequently Asked Questions

Exactly how Do I Determine the Right Container for Hazardous Products?

To figure here out the ideal container for unsafe products, one must review compatibility with the material, think about the container's product, check for regulatory conformity, and analyze ability and security features to assure correct handling and storage.Can Mass Containers Be Personalized for Certain Products?

Yes, bulk containers can be tailored for particular products. used collapsible bulk containers. Numerous features, such as style, dimension, and material, can be tailored to fulfill one-of-a-kind requirements, ensuring suitable security and efficiency for transferring and storing different productsWhat Is the Average Life-span of Different Bulk Container Kind?

The typical lifespan of mass container types differs; plastic containers last 5-10 years, steel containers 10-20 years, and wood containers usually last 3-7 years, depending on usage, upkeep, and environmental conditions.Just how Should I Clean and Maintain Mass Containers?

To cleanse and keep bulk containers, one ought to regularly check for damages, eliminate residue, laundry with proper detergents, rinse thoroughly, and guarantee proper drying out prior to storage. Adhering to maker standards improves long life and safety and security during usage.Exist Rental Choices for Mass Containers Available?

Yes, numerous business offer rental alternatives for bulk containers, providing versatility for organizations. These leasings can fit various needs, permitting companies to manage inventory successfully without the commitment of purchasing containers outright.Sturdiness and stamina are important factors in picking products for mass containers, as they directly influence the container's ability to endure different environmental conditions and handling procedures. Recognizing chemical compatibility is necessary for selecting bulk containers, as the products made use of need to stand up to the certain substances they will certainly hold. Recognizing weight capacity is crucial for companies aiming to enhance their mass container effectiveness. Regulative conformity and security criteria play a necessary role in the option of bulk containers for organizations. While several organizations focus on sustainability, cost-effectiveness continues to be a crucial factor when choosing bulk containers.

Report this wiki page